History of Sherardizing

Sherardizing was originally developed by an English metallurgist Sherard Cowper-Coles who invented and patented the process over 120 years ago. Originally it was named Vapour galvanising or dry galvanising. This became “sherardizing” in honor to his name years later. Although modern technology is now used to improve efficiency, the sherardize coating has consistently been proven to succeed where many alternatives have failed.

Sherardizing was used for example on iron coins around the 1920s, some of these coins today still show no rust, highlighting the superlatively reliable nature of Sherardizing itself shown through tangible evidence.

Technical Properties

The hot dip galvanized method of application happens in only a few minutes which only allows the zinc atoms a short period of time to diffuse into the base steel and form the iron alloyed layers above. This results in an almost non-existent Gamma layer and further alloy layers with lower iron content compared to sherardizing.

A sherardize coating is formed over a 90 – 150 minute period resulting in a thicker diffused layer into the base steel and also allowing iron to diffuse through all further layers avoiding the softer pure outer zinc layer.

The more heavily alloyed the coating is with iron, the denser and more stable the structure.

Accelerated weather exposure testing conducted by CSIRO (Commonwealth Scientific and Industrial Research Organisation) in Australia over a three year period has proven that the corrosion rate of pure zinc is more than double that of zinc-iron alloys. Given that a sherardize coating has no pure zinc layer as well as a higher percentage of alloyed iron, a sherardize coating has a lower coating mass loss rate than of pure zinc under identical corrosive action.

Correspondingly, a sherardize surface will require a lower coating thickness for equivalent performance.

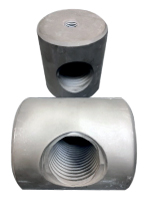

A sherardized coating is uniform on all accessible surfaces without any peak build up. The consistency is produced during diffusion of the zinc atoms whilst base steel components are rotated enabling consistent exposure throughout the process. The elimination of solidifying zinc build up and uniformity is ideal for coating intricate and irregular shapes which would otherwise be difficult to achieve with hot dip galvanizing.

A sherardized coating is uniform on all accessible surfaces without any peak build up. The consistency is produced during diffusion of the zinc atoms whilst base steel components are rotated enabling consistent exposure throughout the process. The elimination of solidifying zinc build up and uniformity is ideal for coating intricate and irregular shapes which would otherwise be difficult to achieve with hot dip galvanizing.